Behind the Scenes: The Finishing Department

Process Matters

The journey matters and at Stoll, an important part of a product's journey is the finishing department. This part of the process is where the final look of the product becomes a reality, transforming raw metal and steel into a beautiful product.

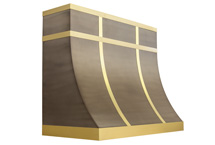

For years, finishes at Stoll were available in any color--as long as it was Black or Brass. These modest beginnings have grown to a myriad of over 50 finishes from basic powder coats to stunning hand-applied finishes that are truly one of a kind.

Powder Coat: A Tradition of Long-Lasting Durability

Powder coating is a dry coating process that was introduced in the 1960s. Stoll introduced its first powder coat booth in 2011 and now our powder coat line boasts of two booths and ovens, along with a staff of six, keeping them busy. Powder coat is applied as a dry powder through an electrostatic process then cured with high heat in a curing oven at over 350 degrees. Yes, you could technically bake cookies in our oven but don’t worry we haven’t tried that. Powder coat is well known for providing a high-quality finish in terms of functionality and looks.

Two-Step Finishes: A True Work of Art

Anyone can apply a good powder coat finish with some attention to detail, but Stoll’s two-step finishes are a true work of art, custom-designed by our talented craftsmen. Our Antique finishes, for example, start as a wet coat that is sprayed on then the craftsman relieves the wet coat before it has completely cured allowing the natural steel to shine through. A clear powder coat is then applied to prevent finishing, corrosion, or fading.

Our Burnished finishes are another special design with the craftsman applying the Burnished finish over a powder coat by hand. This provides an exclusive finish that is unmatched in Craftsmanship and truly one of a kind.

Finishes like Aged Copper & Aged Brass are created by applying a specially formulated rinse to the material and then heating with a torch. Each piece is then clear coated to prevent the copper from continuing to patina. Without a protective clear coat, it would end up Statue-of-Liberty green!

Borne of Necessity and Creativity

The exciting thing about our finishes is that many of them were truly created by the creativity God has placed in each of our gifted team members. Someone in the powder coat department can often be heard saying “What if we….,” and the results are stunning.